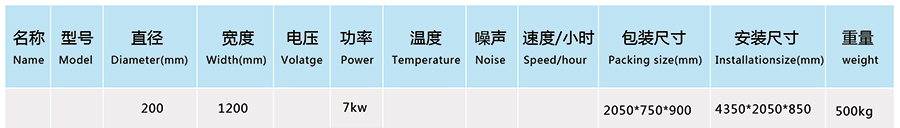

Professional edition ZS-BB

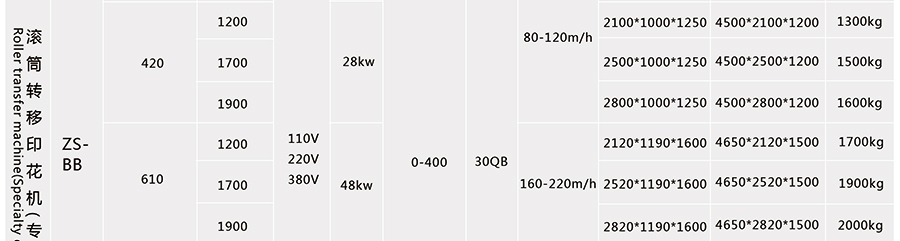

1.Double cylinder structure, internal/external cylindrical drum lathe processing, precision cylindrical grinding machine processing, ensure the drum thickness consistent, fever within + / - 1 ° C.

2.The heat pipe is imported from Taiwan, and the heating tube is soaked in the heat conduction oil and heating up. The heating rate is faster, and the energy saving is more than 15%.

3.Blanket selection of American dupont material, the transfer effect is good, the service life is long.

4.Pneumatic pressure device can be adjusted according to the transfer of different materials. It can be changed faster and brighter.

5.The pressure of the blanket and heating cylinder is consistent, which completely solves the problem of the blanket cooling when shutdown or power failure. It is better to protect the blanket and prolong its life.

6.The machine adopts three - and two-charge functions, and three: two. Suitable for main wear, cutting and readymade garments.

1.Lathing inner circle and circle contains grinding by precision grinding machine,ensure the thickness of roller consistent, difference of temperature is 31 'C Double layers roller,more stable temperature inside the roller to ensure consistent temperature of each point,transfer effect without color difference.

2.The stainless steel heat pipe,imported from taiwan,is all soaked in conduction oil,heats faster and saves 15% energy.

3.Blanket is made by Dupont materials from USA,transfer effect is better and life Is longer.

4.Adopting automatic adjusting device prevents blanket to deviate while working.

5.Pneumatic compression device can regulate the pressure according to different materials,transfer speed is faster and color is more vivid.

6.lnflatable shaft ensures putting cloth and paper with no excursion, rolling tightly and many,labor saving and raising overall sufficiency.

7.Using synchronous rod and pressure balance bar make blanket breakaway,ensure pressure between blanket and roller consistent at each point,and solve the problem of blanket cooling when shut down or out of power,protect blanket and make its life longer.

8.High hardware configurations, line cutting the main walland shaft,error Is controlled In less than 0.02mm.blanket will not go astray.

9.Independent fuel tank makes adding conduction oil convenient. Having the advantage of anti-explosion and high safety.

10.Frequency converter can freely adjust the printing speed,the transfer speed is more stable.

11.You can set idle time according to your ennds to save time.

12.Three puts:put cloth,put transfer paper,and put protective paper.Three rolls: roll cloth,roll used transfer paper,and roll protective paper,lt's suitable for printing roller clolh.cut pieces and garments.

| Product application:clothing, home textiles, handbags, mat, shoes, hats, crafts, toys, advertising supplies. | ||||

|

|

|

|

|

|

||||